Gripping

Inspired by the Octopus, the OctoGripper™ technology naturally conforms to the contour of any object with a firm but gentle grip.

Data integration with other systems

Machine, data interfaces enable integration with other process equipment, order, production and support systems.

Fast & accurate hand-eye coordination

Utilizing the worlds fastest robotic arms, the workforce is easily trained and optimized for consistent, accurate placement and patterns

Inspection

Coordination of vision and gripping system enable inspection capabilities that will continue to advance over time.

Vision

Patend illumination technologies combined with automated visual modeling enables the platform to recognize multiple types of non-uniform objects in varying orientations.

LEAN Inspired production monitoring and remote support

"Lean" is a process management philosophy focused on simplifying processes and reducing waste and cost. The OctoMation™ workforce incorporates the Lean principle of "autonomation" by monotoring a production process and automatically handling events to minimize waste. For example, the platform can be configured to take action such as pausing production or notifying a technician when issues are identified or threshholds crossed. TheOctoMation™ flight recorder captures all relevant system data indexed with product images so that it can be reviewed to diagnose and solve issues.

Because eachOctoMation™ platform is connected to the Internet, notification, investigation, diagnosis, problem resolution and system updates can all be performed remotely from the plant floor or anywhere in the world.

Performance data from allOctoMation™ platforms in your enterprise can be aggregated for a comprehensive picture of production performance and trends.

Special Development and Integration

- Gripping requirements that do not fall within the specifications of existing standard OctoGrippers will requirenew development paid for by the customer based on a written specification. Some operations mayrequire a proof-of-concept prototyping phase prior to finalizing production parts.

- Quality inspection requirements (visual or otherwise) that do not fall within the specifications of existingstandard capability will require new development paid for by the customer based on a written specification.

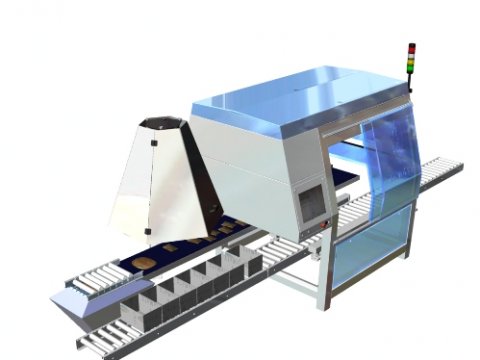

- The OctoPacker platform requires integration at the following points:

- Bag/package input

- Box/carton inputs

- Box output.

- Optional production, notification, and event data integration with internal systems.

OctoMation Engineers will work with customer's engineering staff to communicate interfaces and developan integration plan. While OctoMation engineers will clarify requirements and suggest solutions, implementationof the platform integration points is the responsibility of the customer.